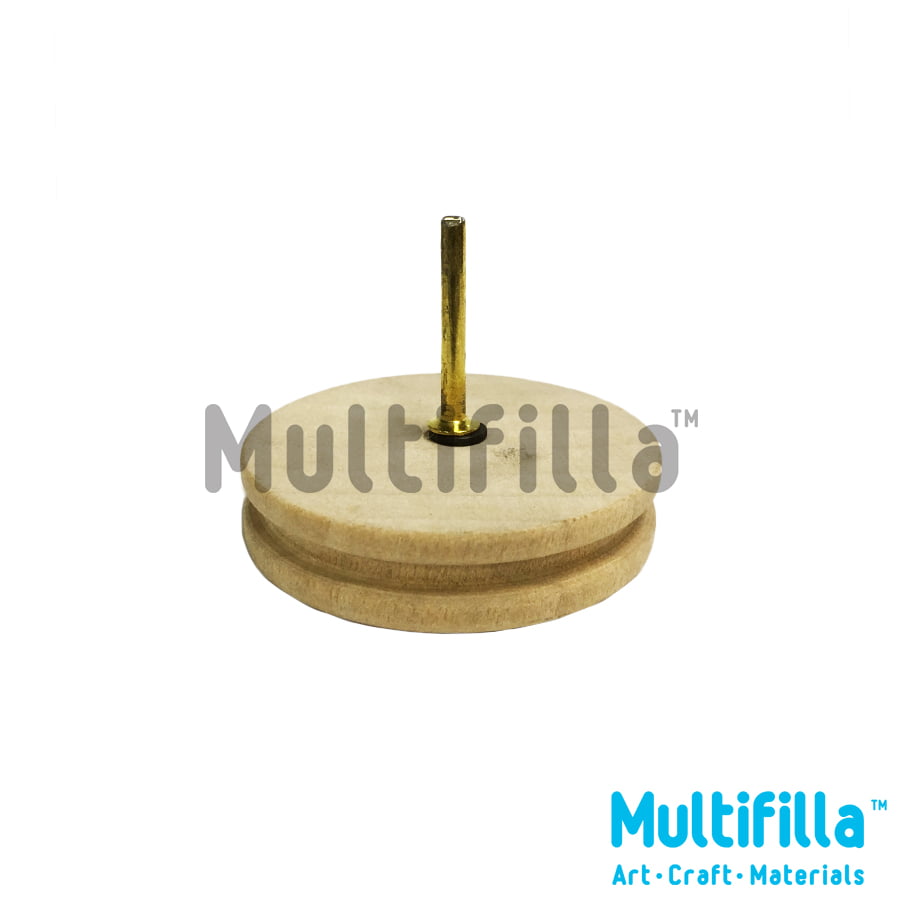

Simple as it look the wood disc is invaluable should a fine leather polished edge is required. Works faster and better then hand burnishing of the leather edges. To achieve a fine polished edge, apply matt sealer with a sponge brush over a presealed and dyed leather edge. Commence buffing with the rotating wood disc clamped on to a electrical hand drill when the matt sealer is about to dry. Occasionally dress the disc groove with carnauba or beewax to friction polish the sealed edge to a professional finish. A sealed, burnished and waxed edge adds value and craftmanship to leather crafts.

The disc groove can be widen while rotating by sanding with sandpaper attached to a dowel to suit the leather thickness.

In polishing metal tool like chisel, plane blades and knives or any other cutting tools except ceramic knives. Dress the wheel with Dialux metal polishing wax. A polished surface much reduce friction and cutting resistance of mini serrations and burs left by grinding stone or whet stone. A mirror polished and honed surface will assist in a smooth clean cut.