Note: In dry cake form. To soften, poke many holes with a screw driver and add water to soak. Knead or plug clay to recondition before use.

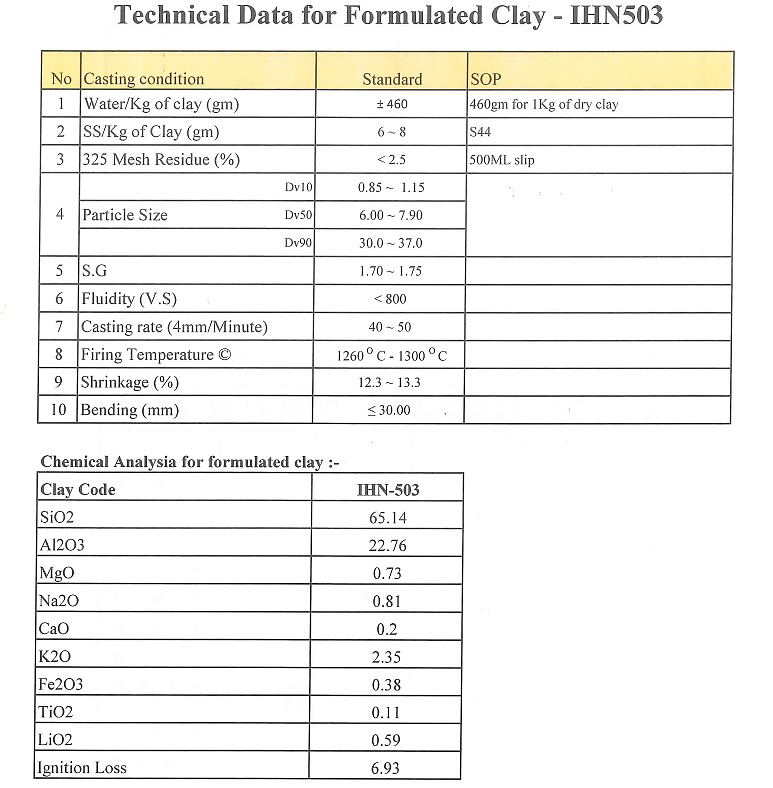

A moist porcelain clay body fired to 1280°C white or blue white under reduction. Formulated for slip casting can be used in sculpting by soaking and kneading with the amount of water to soften clay block. Supplied in block and would dry out naturally in storage. For slip casting blunge with deflocculant and sufficient water into a slurry to cast in Plaster of Paris molds. For consistency gauge water content of slip with hydrometer. Soda ash, sodium silicate, Reotan L and Dispex are examples used singly or a combination in deflocculation. Clay body is fine smooth. Fires white.

In hand building use or throwing addition of Bentonite clay or CMC/tylose increases clay plasticity. However do note iron content in Bentonite clay might affect fired porcelain clay color.

Fire to maturity at 1260°C to 1300°C under oxidising condition and the last 15 minutes in reduction for the nice bluish tint.

Color with velvet underglaze by AMACO generally applied in 3 coatings in greenware stage or to bisque porcelain. Fired to maturity.

Clay of Japanese technology.

Note: Weight content will be lesser as clay dries naturally in storage. Restore weight with water addition and kneading before use.