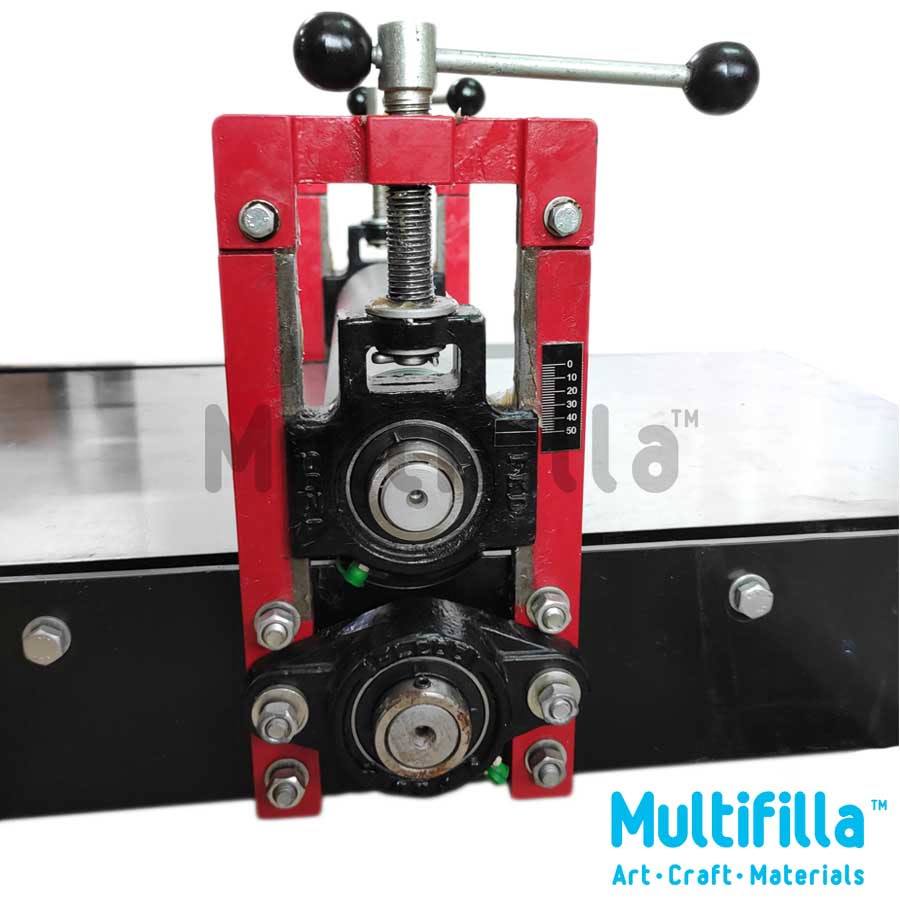

Imported table top etching press 12″ x 24″ length. Manual rolling through triple reduction gears for smooth rotation. Gears metal cover for safety. Heavy solid 70mm diameter metal rollers with four bearings and pillow blocks. Clear identification markings to determine roller maximum throat gap of 25mm. Solid 8mm thick metal bed that prevents bed warping. Bed movement is well supported on ball bearings. Press is very stable weighing 32kg with four holes to bolt or screw on to work table. Complete with 2 felt blankets 30cm x 53cm and spanner.

A press for professional studio use. Suited for metal, wood block, lino printing even card making and floral pressing. Leathercraftsmen would use to laminate, flatten and smoothen flesh side with application of matt sealer. Apply 2 coatings of matt sealer and when semi dry place a plastic sheet on before press rolling several passes to compact and seal the fibres against leather drying. Polymer clay reconditioning placed between 2 heavy duty plastic sheets to soften clay with addition of clay softener. Even for crumbly clay plastic sheets helps in reconditioning in several folds and pass kneading.