A product of USA. Totally stainless steel stirrer for attachment to hand drill. Robust construction die cut and formed from a single plate. Solid welding to shaft. Well designed to minimize air sucking into the mix following the manufacturer recommendation in RPM best suited to the impeller diameter.

For color mixing, cement, plaster, alginate, clay slurry for slip casting, adhesives, resins, soap making, papier mache, and food safe kitchen use in blending sauces, puree, cordial etc. Paper making as a shredder for soaked paper pulp with soda ash mixing into a pulp in paper recycling or with virgin cellulose fibres.

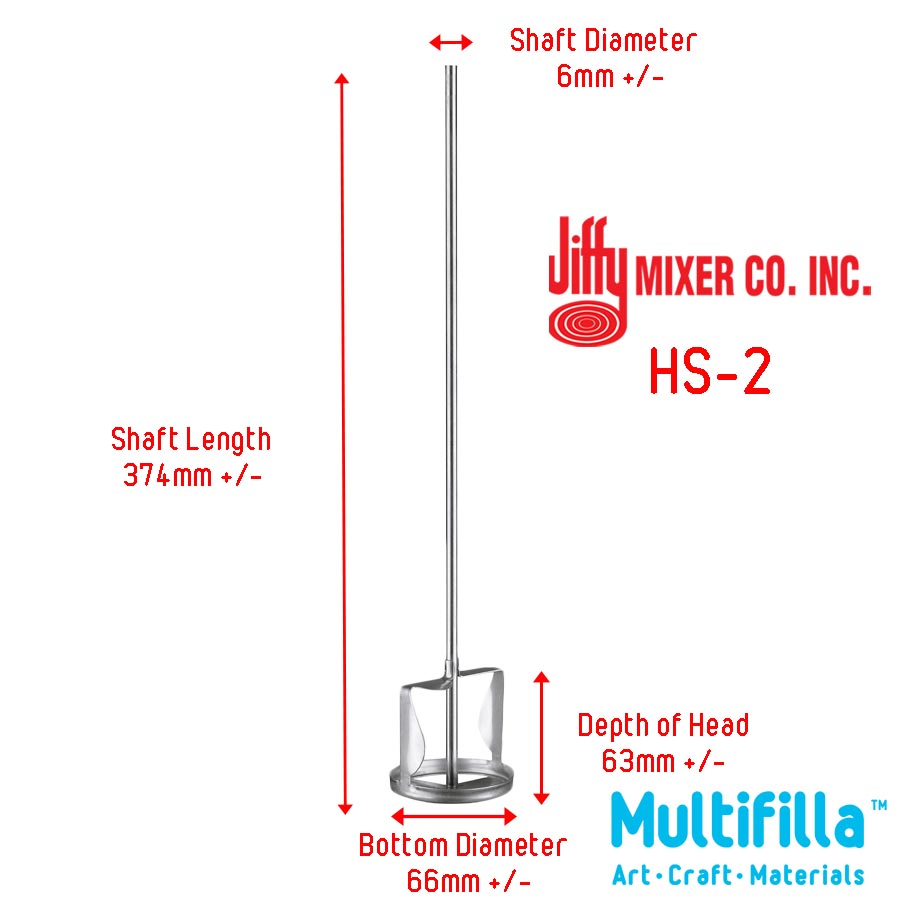

HS-2

Made of 304 polished stainless steel, the HS-2 model is designed for medium jobs in 1-2 gal. (4-8 qt.) containers. It easily fits any 1/4″ electric chucked power tool.

Product Description

The HS-2 model is designed for a max speed of 1200 RPMS. Tools with 450-750 RPMS get the best rate of thorough mixing. Mixers can be permanently installed if desired.

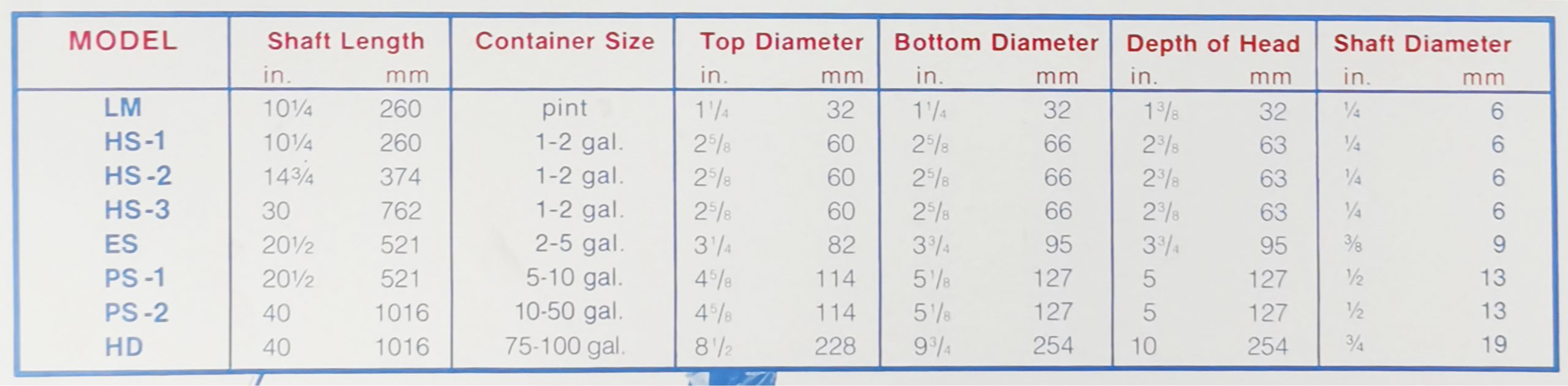

| Shaft Length | Container Size | Top Diameter | Bottom Diameter | Depth of Head | Shaft Diameter | |||||

| in. | mm | in. | mm | in. | mm | in. | mm | in. | mm | |

| 14 3/4 | 375 | 1-2 gal. | 2 5/8 | 67 | 2 5/8 | 67 | 2 3/8 | 60 | 1/4 | 6 |

Jiffy Mixer is an all purpose, heavy duty, extremely efficient industrial/commercial mixer.

It is designed to quickly and thoroughly mix dense and viscous substances in an open container. It eliminates waste and unwanted aeration of materials in addition to cutting mixing time up to 90%. It is equally effective with liquids, dry materials, liquid and dry materials combined, or multiple component materials. Made of stainless steel 304, its patented construction and design is for mixing, not just stirring.

It’s various sizes fit standard 1/4″, 3/8″, 1/2″, 3/4″ chucked power tools. It has two sets of specially welded blades. The vertical ones keep the mixing action between them, the horizontal ones employ an exclusive hydraulic-glow principle that prevents sucking air. In addition, the horizontal blades pull the high density material up from the bottom while forcing the low viscosity solvents down from the top. The leading edge of the lower horizontal blade will scrape the bottom of the mixing container to bring all settled material particles into the mixing unit.

No Splashing-Submerge mixer into materials to be mixed before starting motor; shut motor off before allowing mixing unit to reach surface of the mixed materials.

Will not draw in air -The exclusive hydraulic-flow action of the horizontal blades force just the materials from the upper and lower areas of the container into the mixer.

Thorough Mixing-The two vertical blades keep the main mixing action inside the unit, thus increasing the efficiency of the horizontal blades by exerting pressure on the materials being mixed.

Fast Mixing – Cuts time up to 90%- A 5 gallon can of separated paint can be thoroughly mixed and blended in about 60 seconds.

Special Weld Construction-Made entirely of rugged stainless steel 304, all stress joints are specially welded for extra strength so it is virtually impossible for them to break even when mixing extremely heavy materials such as slurry and mud.

Puncture-Proof/Safe Operation-The exclusive patented protective ring design prevents puncture or damage to the walls of the mixing containers. It also prevents the breaking or bending of the horizontal blades. In addition, the ring eliminates accidents should the mixer be accidentally started outside of a container.

Quick, Easy, Cleanup-Just rotate mixer in appropriate thinner or solvent.